A Smarter, More Hassle-Free Partner For Dental Laboratory

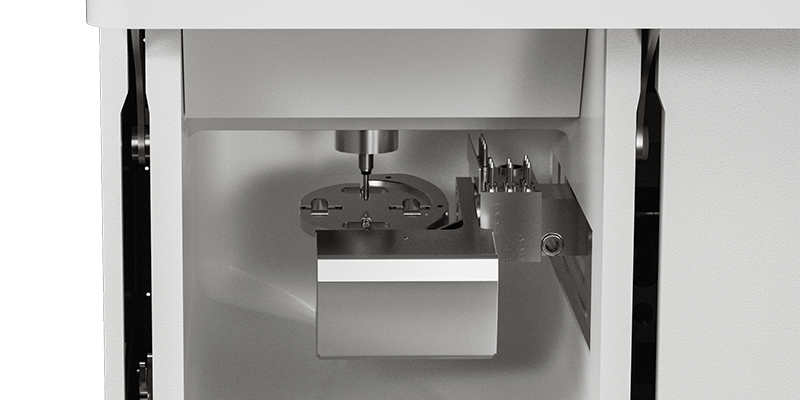

Dust-Proof Slides Extend Operational Lifespan

Innovative dust-proof slide technology seals internal components, shielding the machine from airborne contaminants. This advanced design significantly reduces maintenance requirements and prolongs operational lifespan of the P53 dry dental milling machine, delivering a more efficient, reliable, and durable machining experience for users.

Streamlined Material Switching With Custom BK-1 Clamps

The innovative BK-1 clamp design enables rapid disc and block material changes in seconds, optimizing production efficiency.

Precision 90° Milling For Realistic Restorations

The five-axis synchronous technology enables 90° vertical aesthetic dry milling, complemented by a 0.3mm micro-carving cutter. This intelligent solution precisely integrates efficient, realistic restoration, ensuring consistently high-quality dental prosthetics that deliver natural-looking, life-like outcomes for patients.

Smart Remote Control

MillMind software provides remote control, smart milling reminders, and tool life monitoring capabilities enable effective production oversight.

Precision And Stability With One-Click Calibration

One-click smart calibration simplifies operations, automatically optimizing the machine’s accuracy and stability. This feature reduces milling errors, minimizes material waste, and enhances overall efficiency, empowering users to consistently produce high-precision dental prosthetics with exceptional quality and reliability.

01. C-Clamp Design

03. CNC Multi-Machine Control

05. Tool Life Monitoring

02. Smart LED Display Strip

04. Resume Milling At Breakpoint

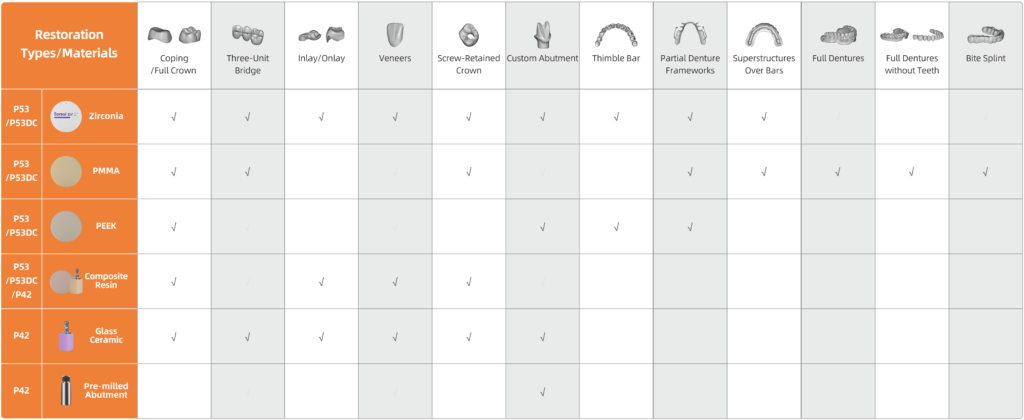

Restoration Types/Materials

Specification

| Model | P53 |

| Dimension | 443.5*718*628.5mm |

| Weight | 87kg |

| Input Voltage | AC 100-240V |

| Maximum Power | 1.1KW |

| Spindle Power | 0.35KW (max) |

| Number of Axes | Five-axis simultaneous |

| Milling Range | X/Y/Z: 167/200/90mm, A:±30° B:±360° |

| Milling Type | Dry milling |

| Max Spindle Speed | 40,000rpm |

| Max Feed Rate | 3000mm/min |

| Tool Quantity | 11 |

| Tool Change Method | Automatic (air pressure > 0.5MPa) |

| Spindle Cooling | Compressed air (air pressure 0.15~0.20MPa) |

| Materials | Zirconia, wax, PMMA, PEEK, cobalt-chromium soft metal, composites |

| Milling Time | Coping: Zirconia 10 minutes, Wax 4.5 minutes Full crown: Zirconia 13 minutes, |

| Wax 5.5 minutes | |

| Material Size | Discs: height 10-30mm, diameter 98mm Blocks up to 40*20*20mm |

| Spindle Clamping Diameter | Φ4.0mm |

| CAM Support | UPCAM, Millbox |

| Data Transmission | Network interface |