Superior Quality, Immediate Fit

The P42 dental wet milling machine can process 3 ceramic blocks or 1 titanium rod simultaneously, with deep software-hardware integration. It seamlessly integrates with the SOREAL Immediate Restoration System, simplifying the digital workflow from scanning and design to milling. Features like pure water milling, undercut removal, remote control, and automatic calibration ensure precision and quality. This versatile, user-friendly solution significantly boosts the efficiency of restorative creations.

Pure Water Milling, Cost-Efficient & Eco-Friendly

Pure water grinding and milling eliminates additives, reducing costs and material wear. This eco-friendly approach simplifies operations by avoiding complex waste disposal, ushering in a safer, more economical era of dental restorations.

Precise Undercut Removal, No Manual Grinding

The A-axis’ ±20° oscillation and UPCAM technology enable targeted undercut removal, avoiding complex manual adjustments. This precise machining process guarantees a perfect fit for dental restorations of up3d dental milling machine P42.

Seamless System Integration

The intuitive control system seamlessly integrates with the SOREAL Immediate Restoration System, streamlining the digital workflow from scanning and designing to milling. This user-friendly simplicity improves efficiency and better meets clinical needs.

Smart Remote Control

MillMind software provides remote control, smart milling reminders, and tool life monitoring capabilities enable effective production oversight.

Versatile, Multi-Material Capability

Handles glass ceramics, composite resins, and titanium rods for diverse restorations. This dental wet milling machine’s ability to process three materials simultaneously boosts production efficiency, meeting the varied needs of clinics and dental labs.

01. High Standard Development

Water circulation and air cooling protect the spindle, ensuring long-term stability when milling hard materials. The German-engineered CAM system meets personalized processing requirements.

03. One-Click Automatic Calibration

Integrated UPCAM technology automatically calculates tool wear, enabling strategic planning to reduce the risk of porcelain breakage and processing failures for consistent, high-quality results.

02. Precision-Cast Structure

The cast integrated frame and high-precision components, paired with the UP3D control system, deliver precise, stable milling from 0.2mm ultra-thin to conventional veneers.

04. Resume Milling At Breakpoint

The software automatically continues milling from the last interrupted step, eliminating repeated work. This feature boosts efficiency by at least 80%, saving time and resources.

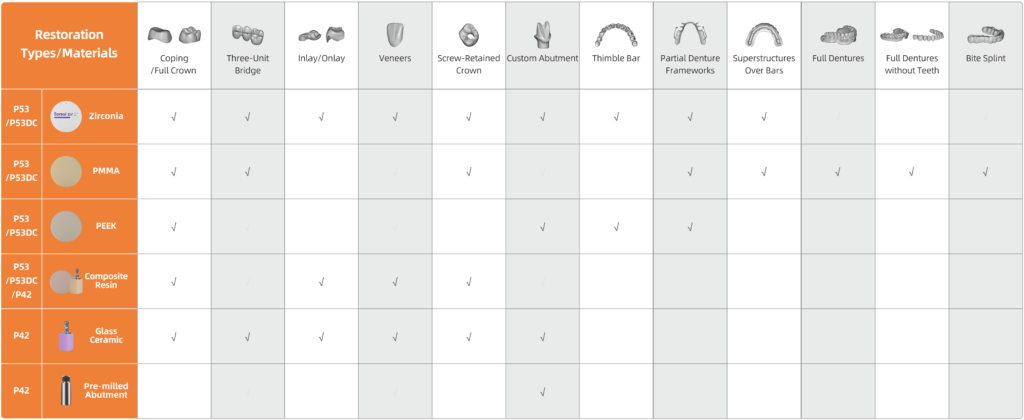

Restoration Types/Materials

Specification

| Model | P42 |

| Fields of application | Wet machining |

| Number of Axes | 4 |

| Materials | Glass ceramics, Titanium, Composite resin, PMMA |

| Indications | Coping, anatomical crown, screw-retained crown, inlay, onlay, veneer,telescopic crown, implant abutments |

| Linear Axes X/Y/Z | Driven by precision ball screw (distance of travel of X-/Y-/Z-axis: 110/75/50) |

| ±360° | |

| Lighting | LED lighting with status display |

| Camera System | Built-in camera for monitoring grinding status |

| General | Spindle pneumatic tool change (air pressure > 0.5MPa) |

| Speed | Up to 60,000rpm |

| Tool Holder Diameter Compatibility | 4Φ |

| Spindle Power | 0.39KW (max) |

| Tool Change | Tool magazine for 6 tools |

| Compressed Air | Pressure: 0.5-0.8MPa, consumption: 45 L/min |

| Voltage/Frequency | 100VAC ~ 130VAC, 200VAC ~ 235VAC (Selectable between two ranges), 50~60Hz |

| Data Transmission | Wi-Fi, USB, Ethernet |

| Operating Temperature | 10℃~50℃ |

| Air Moisture | Below 93% RH (relative), non-condensing |

| Dimensions | WxDxH= 400*560*565 (mm) |

| Weight | 80kg |

| CAM Software | Premill abutment jig for multiple implant systems Premill abutment jig for multiple implant systems (optional) |

| Jig | Premill abutment jig for multiple implant systems (optional) |