Superior Milling, Efficiency First

The advanced five-axis milling machine features a 12-slot disc design for uninterrupted 24-hour automatic material and tool changes. This ensures stable, high-volume output even in unmanned dental labs. Paired with the custom BK-1 clamp for seamless disc-block switching, this dental mill combines 90° vertical aesthetic processing and 0.3mm micro-carving to deliver consistently precise, efficient, and natural-looking dental restorations.

Automatic Material Change Large Capacity Material Library

Integrated automation and 12-fold material library enable continuous 24/7 milling with automatic material switching. Advanced RFID and robotic arm technology ensure precise, efficient, and stable material changes for high-volume production.

Versatile Material Compatibility, Instant Switching

Supports a wide range of materials including zirconia, wax, PMMA, PEEK, cobalt-chromium, and composite resin. P53DC dry milling machine is equipped with the custom BK-1 clamp for instant switching between disc and block formats for efficient multitasking.

90° Precision Milling

The five-axis synchronous technology supports 90° vertical aesthetic processing. Paired with a 0.3mm micro-carving cutter, this dental lab milling machine delivers precise, efficient milling for high-quality, realistic dental restorations.

Smart Remote Control, Enhanced Productivity And Efficiency

MillMind software provides remote control, smart milling reminders, and tool life monitoring capabilities enable effective production oversight.

Negative Ion Generator Optimized Cleaning Efficiency

Integrates negative ion technology to significantly reduce static from resin debris, enhancing cleaning efficiency. This creates a tidy work environment and fosters a comfortable machining experience.

01. Automatic Tool Changing

The 11-tool library enables continuous milling of diverse materials without interruption, boosting production efficiency, precision, and stability while lowering maintenance costs for a more seamless, cost-effective manufacturing process.

03. Dental Milling Tool Life Monitoring

Integrated UPCAM technology automatically calculates tool wear, enabling strategic planning to reduce the risk of porcelain breakage and processing failures for consistent, high-quality results.

02. Resume Milling At Breakpoint

The software automatically continues milling from the last interrupted step, eliminating repeated work. This feature boosts efficiency by at least 80%, saving time and resources.

04. Dust-Proof Slides

Innovative dust-proof slide technology seals internal components, shielding the machine from airborne contaminants.

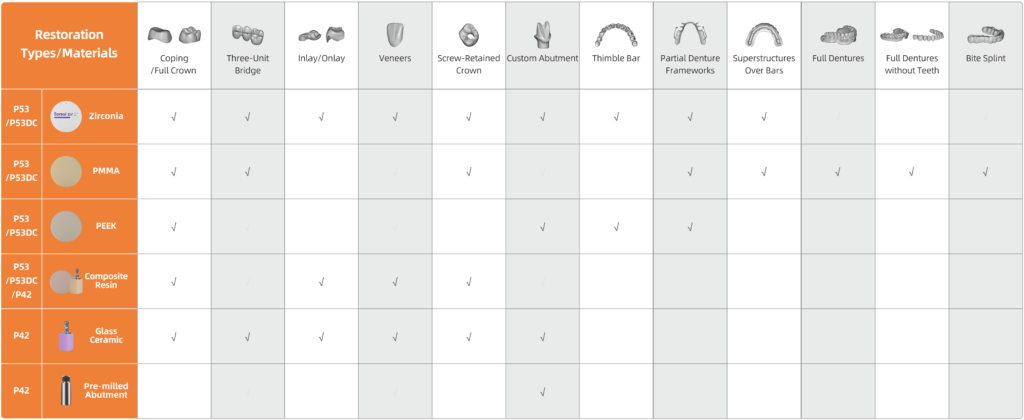

Restoration Types/Materials

Specification

| Model | P53DC |

| Dimension | 875*720*630mm |

| Weight | 130kg |

| Input Voltage | AC 100-240V |

| Maximum Power | 1.1KW |

| Spindle Power | 0.35KW (max) |

| Number of Axes | Five-axis simultaneous |

| Milling Range | X/Y/Z: 167/200/90mm, A:±30° B:±360° |

| Milling Type | Dry milling |

| Max Spindle Speed | 40,000rpm |

| Max Feed Rate | 3000mm/min |

| Tool Quantity | 11 |

| Disc Library Quantity | 12 |

| Tool Change Method | Automatic (air pressure > 0.35MPa) |

| Spindle Cooling | Compressed air (air pressure 0.15~0.20MPa) |

| Materials | Zirconia, wax, PMMA, PEEK, cobalt-chromium soft metal, composites |

| Milling Time | Coping: Zirconia 10 minutes, Wax 4.5 minutes Full crown: Zirconia 13 minutes, Wax 5.5 minutes |

| Material Size | Discs: height 10-30mm, diameter 98mm Blocks up to 40*20*20mm |

| Spindle Clamping Diameter | Φ4.0mm |

| CAM Support | UPCAM, Millbox |

| Data Transmission | Network interface |