Smart Servo System For Supreme Performance

High Precision Servo System Round-The-Clock Stable Production

The full-servo drive system precisely compensates for milling vibrations, ensuring stable and efficient production 24 hours a day. This allows for the effortless precision dental milling of complex restorations.

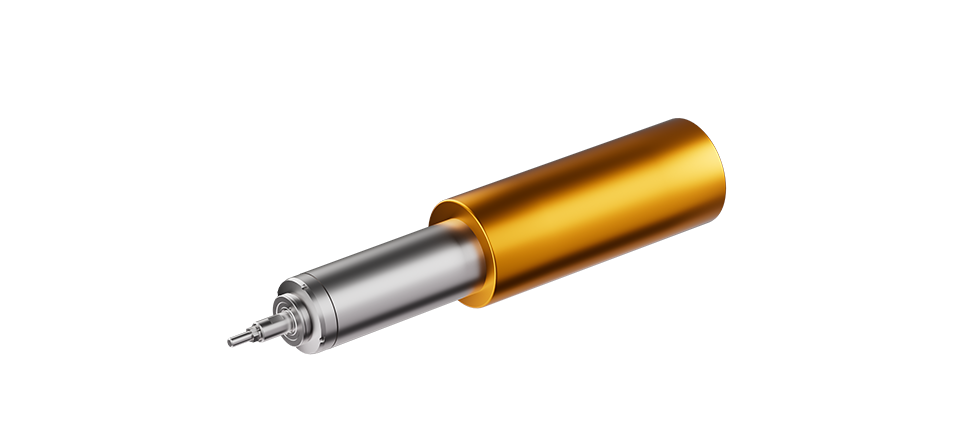

No Compressed Air Needed German Precision Engineering

Featuring a high-speed German-imported electric spindle with speeds up to 60,000rpm, combined with no compressed air needed design, this setup allows for plug & mill operation. Not only giving users maximum freedom in choosing the installation site but also saving them the cost of running a compressor. Driven by superior German engineering, this UP3D milling machine effortlessly handles the milling the hard materials.

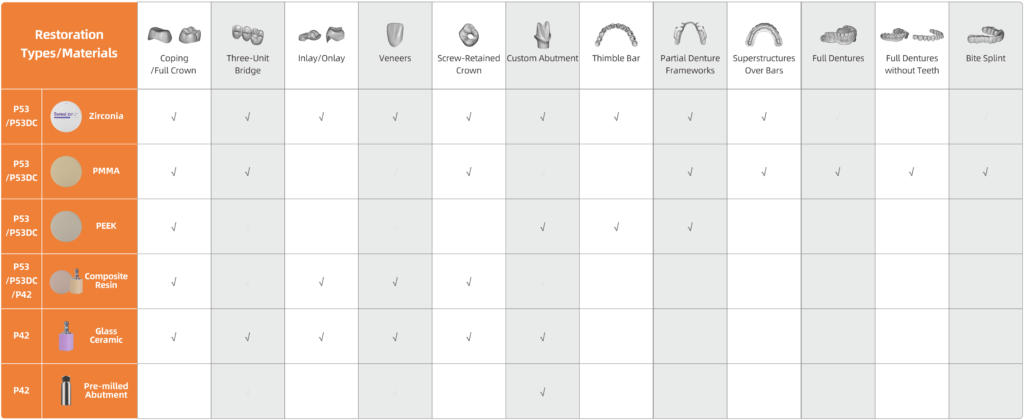

Materials Flexibility Enhancement Through Custom Solutions

The device supports a wide range of materials, including Zirconia, wax, PMMA, PEEK, composite resin, and soft metals, and is compatible with both disc and block specifications. It offers customized, efficient restoration solutions designed to significantly enhance production efficiency.

Smart Remote Control Enhancing Productivity And Efficiency

Remote control through MillMind software, along with smart milling reminders and tool life monitoring, effectively supervising production status and significantly boosts production efficiency.

01. Integrated Dustproof Design

03. Generous Working Chamber

02. Reduce Maintenance Costs

Restoration Types/Materials

Specification

| General | |

| Model | P55D |

| Fields of Application | Dry machining |

| Materials | Zirconia,wax,PMMA, PEEK, composite resin,soft milling CoCr sintering metal |

| Material Specifications | Discs: height 10-30mm,diameter 98.5mm Blocks up to 40*20*20mm(Max) |

| Indications | Crowns,anatomical crowns,screw-retained crowns, inlaysonlays,veneers,telescopic crowns, abutments, bite splintsfull dentures etc. |

| Base System | |

| Construction | Machine bed made of solid cast aluminum body |

| Number of Axes | 5-axis |

| Housing | Steel, white high-gloss paint, main view face molded byinjection |

| Linear Axes (X/Y/Z) | Precision ball screw drive; Travel:104*60*100mm |

| Rotary Axes (A/B) | A-axis:360°, B-axis: ±33° |

| Control Unit | 5-axis precision full servo drive system |

| Lighting | LED lighting inside the working chamber, with additionalstatus display |

| Power | 1.0KW |

| Spinle | |

| General | High-frequency spindle, automatic tool change |

| Speed | Up to 60,000 rpm |

| Tool Holding Diameter | Φ4 |

| Linear Axes (X/Y/Z) | Precision ball screw drive; Trave: 155*110*95mm |

| Power | Max 0.8KW |

| Automatim | |

| Tool Change | Tool magazine for 13 tools, length measurement and tool breakage monitoring via precision measuring key |

| Connection Requirements | |

| Voltage | 100VAC-130VAC, 200VAC-235VAC (selectable), 50-60Hz |

| Dust Extraction | Filter level: M; Flow rate: 2500L/min |

| Data | Wi-fi, USB, Ethernet port |

| Environmental Conditions | |

| Operating Temperature | Between 10℃ and 35℃ |

| Air Moisture | Below 80% (relative), non-condensing |

| Dimensions & Weights | |

| Dimensions (W/D/H) | 442*560*704mm |

| Weight | 106kg |

| Scope of Delivery | |

| CAM Software | UPCAM, Millbox |